Project Introduction

At Students for the Exploration and Development of Space (SEDS) at Penn State, I am the lead propulsion engineer for the solid propulsion group. On this team, I have been leading a small group of engineers to design and manufacture a 2.5kN APCP-based motor for the 2022 Spaceport America Cup. This page will provide details on the motor we are making, design processes, and results (as they come).

Propellant Overview

The propellant that we will be recreating was originally manufactured by MIT rocket team and is called “Cherry Limeade.” The formula for this propellant is shown below in Table 1.

TABLE 1: CHERRY LIMEADE COMPOSITION

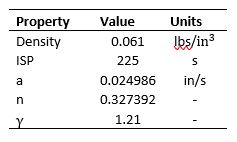

The expected propellant characteristics were also provided by MIT and are shown in Table 2. By having access to this data early on, it allowed our team to begin sizing the motor for our goals.

TABLE 2: CHERRY LIMEADE PROPERTIES

Data Acquisition Systems

To validate the burn rate, capture thrust curves, and measure pressure, a data acquisition system (DAQ) needed to be developed for this process. The DAQ of interest was required to have a load cell and pressure transducer to produce the necessary data for the Spaceport America Cup.

We selected a DI-1100 DAQ created by DataQ due to it’s low cost and ease of use. A low cost 1600 psi pressure transducer was acquired from Walmart, and a 20kgf and 500kgf load cell were acquired from Amazon.

Images showing the completed product and circuit will be provided upon completion.

Test Stand

Pictured in Figure 2, a vertical test stand was selected for testing the motor. The test stand design was made by two undergraduate students within the group and is dominantly made from 8020 stock. The motor will be held in place by two metal tubes bolted to the vertical post. The motor will sit on a mount that is connected to a load cell. The forward closure is tapped, allowing a pressure line to extend out and connect to the pressure transducer.

IN-PROGRESS

We are currently trying to get approval to order chemicals and manufacture on campus, with the goal of acquiring all materials before the end of the Fall 2021 semester. To accomplish this task, we have pulled together a document detailing our plans and evaluating safety risks. This document is provided below for reference.