Project Introduction

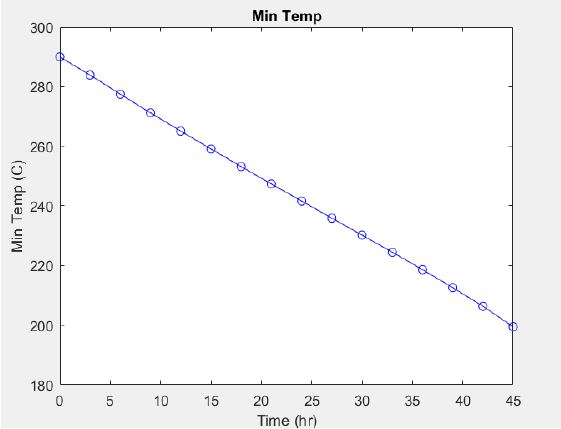

For the final project of my undergraduate numerical methods class, I was tasked with determining the steady-state temperature distribution for a long, thin, cylindrical rod positioned vertically between two constant temperature blocks. In addition to this, a scenario where the heater for the lower block is malfunctioning will be evaluated. In this case, a temperature drop of 8% will occur every 3 hours.

Problem Statement

For this problem, only conduction and convection were evaluated. This will be treated as a 1D problem due to the small cross-sectional area of the rod. The necessary boundary conditions are supplied below in the table.

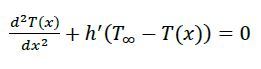

The system can be described by the following second-order differentiable equation:

Using the finite-difference method (FDM), the formula can be discretized into a programmable format.

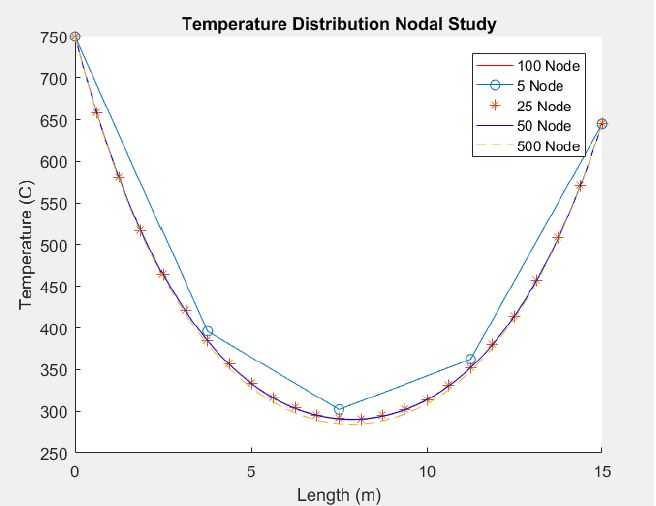

Mesh sizes of 5, 25, 50, and 500 will be evaluated to determine the most accurate sizing. For the additional scenario, temperature decay is evaluated for 45 hours. Lastly, MATLAB will be utilized to solve this problem.

Results

From the plots, a minimum temperature of approximately 300C is determined at the center of the rod. By increasing the number of nodes, a more accurate solution was determined. The 100 point grid values were treated as the real solution. When comparing the values determined by the various node sizes, it was found that the 50 node mesh produced the least percent error, with a value of 0.0673 %.