Project Introduction

Liquid bipropellant rockets are one of the most common rockets used in industry. Being that my goal is to work in rocket propulsion, it seemed worthwhile to gain experience at the collegiate level. The goal is to create a liquid propulsion system suitable for the 10k – SRAD Liquid category at Spaceport America Cup. Once the design is complete, I would like to propose it to the penn state rocketry team and get others involved. Keep in mind that this is an ongoing project. Updates will be provided as progress is made.

Background Research

I began this project by performing extensive research on different fuels and oxidizers with readily available information and research papers. Outlined below are commonly used fuel and oxidizer systems.

| Fuel | Oxidizer |

|---|---|

| Liquid Methane (LCH4) | Liquid Oxygen (LOX) |

| Kerosene (RP-1) | High-Test Peroxide (HTP) |

| Ethanol | Nitrous Oxide (N2O) |

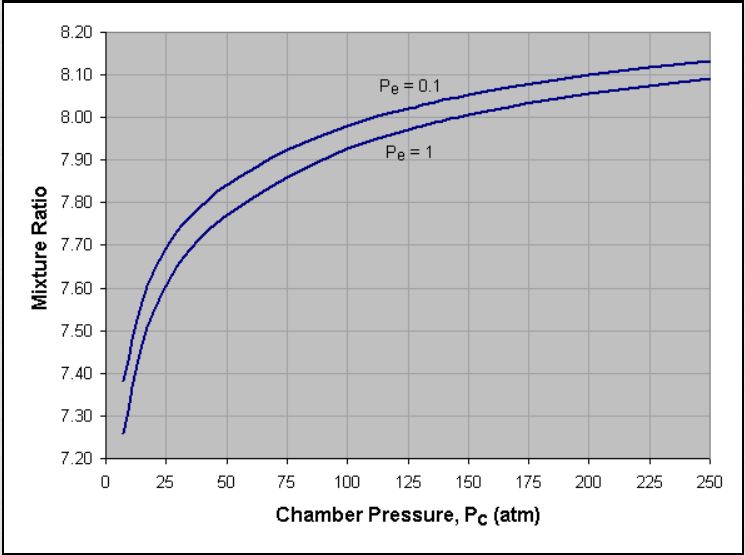

Due to low cost and system requirements, the combination of kerosene and HTP were selected. Cryogenics systems are more costly and increase the complexity of design. As this is my first attempt, the selected combination seemed more approachable. Next, desired chamber pressures and oxidizer to fuel ratios (O/F) needed to be selected. The left image shows the results of using NASA CEA (combustion equilibrium calculator) to test variations in these parameters. The right image shows publicly available data. While CEA indicates that an optimum O/F ratio of 6.5 would produce the highest ISP, much of the literature and available data use ratios of 7.65. Because of the availability of comparative information, and O/F ratio of 7.65 was selected.

Performance Calculations

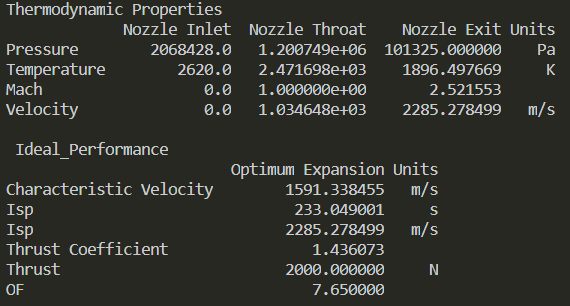

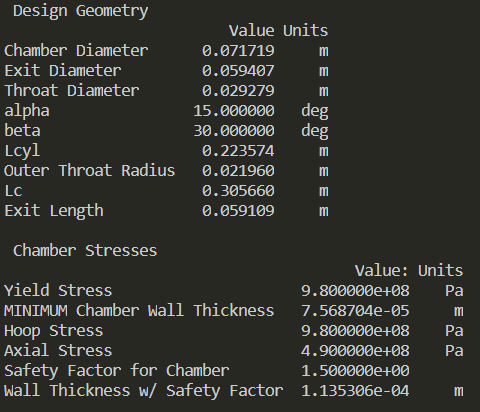

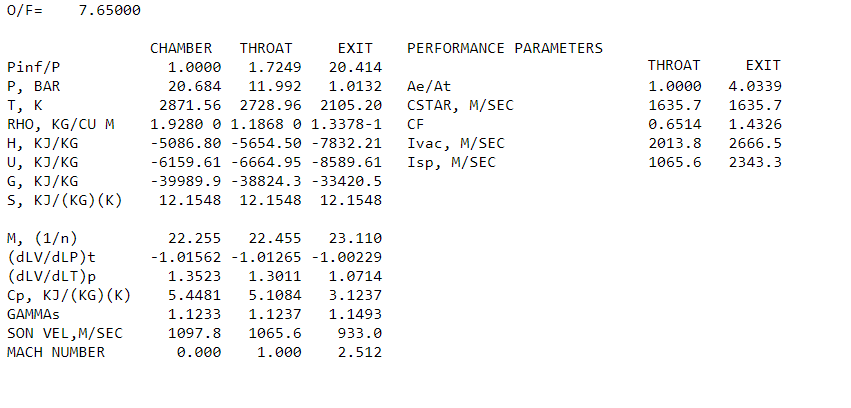

Once the optimal O/F ratio and chamber pressure was determined, CEA was again utilized to find other useful parameters required for calculating performance. The results at 300 psi are shown below.

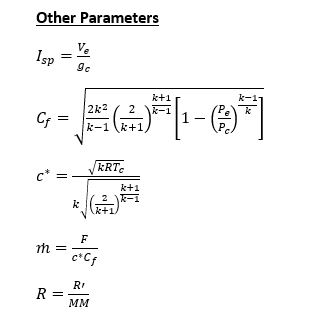

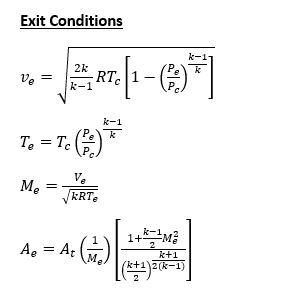

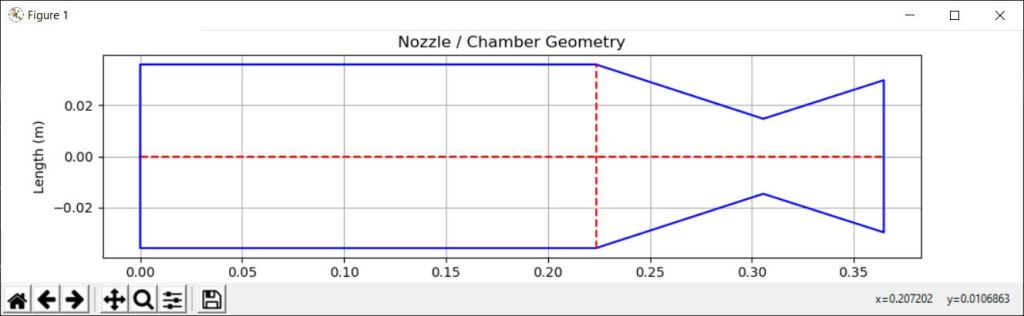

To learn as much as I could, I opted to develop my own python code to perform liquid propulsion analysis, as well as assist in injector design and heat transfer studies. Currently, I have finished the performance analysis and am actively working on the heat transfer studies. This is being used in conjunction with Rocket Propulsion Analysis (RPA) software to validate my results. When it is finished, I will convert it to an executable file for public use. I have listed some of the formulas implemented below.

Heat Transfer Analysis

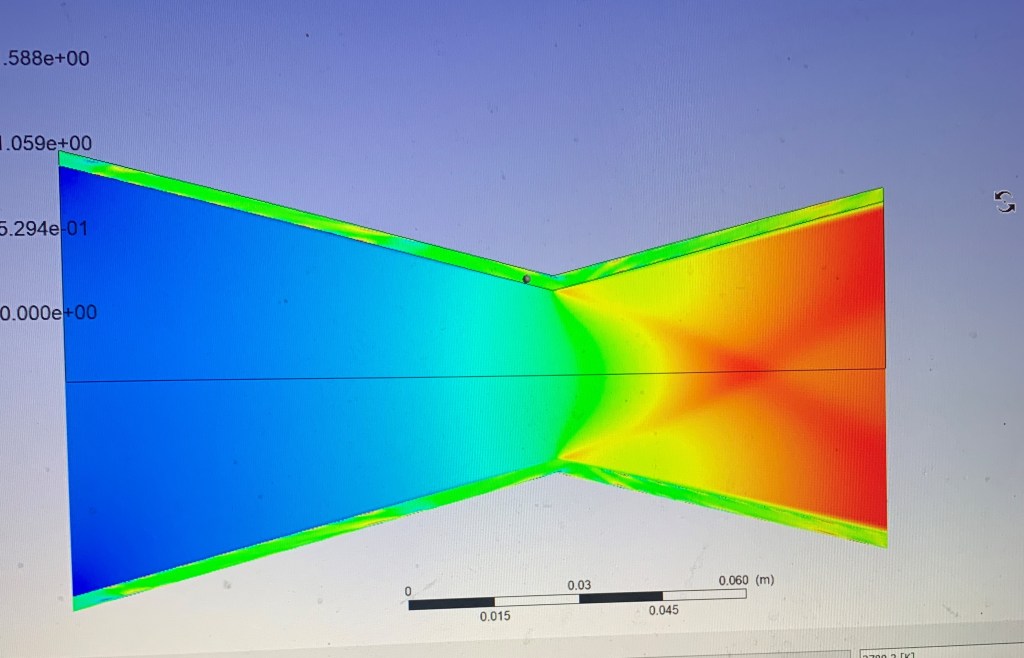

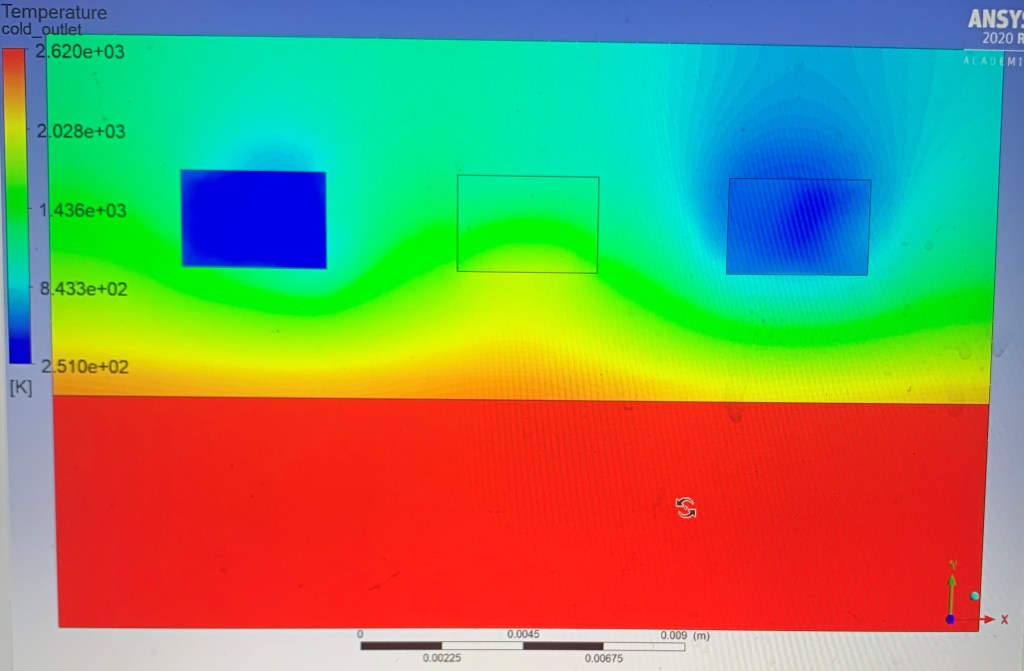

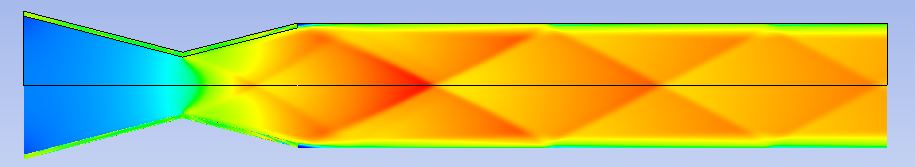

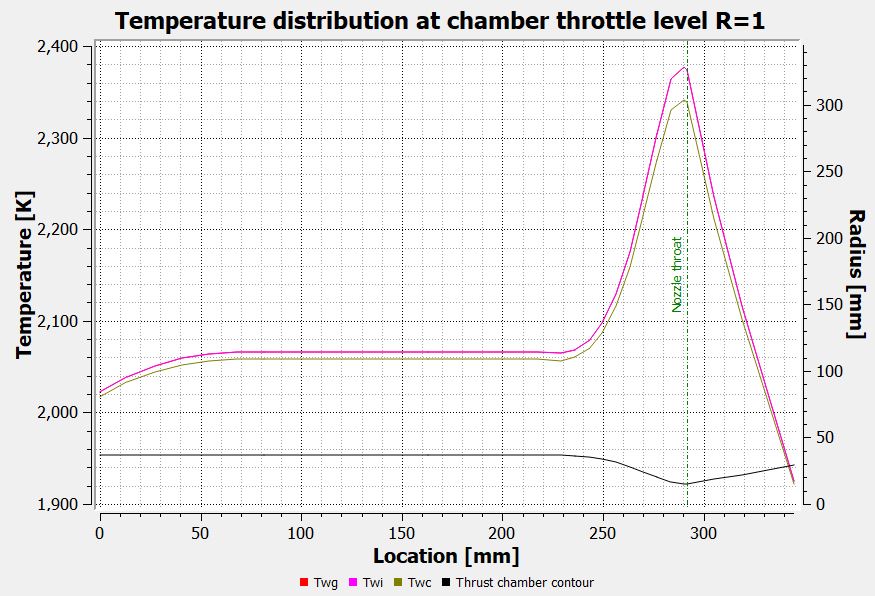

Using RPA, I began evaluating the expected wall temperature, shown below. From this analysis, the anticipated wall temperature is nearly 2,400 Kelvin. The nozzle/chamber will likely be additively manufactured from Inconel 718 or a GRCop Alloy. Additionally, a regenerative cooling system will be implemented to assist with cooling. I am actively carrying out 2D and 3D simulations in ANSYS to determine the required coolant velocity and channel sizes.

At this time, I have decided that I may be switching to LOX as the oxidizer due to cost and accessibility, though this still is up in the air.

PLEASE WAIT FOR FURTHER UPDATES